Chemical Optimization

We’ve been perfecting oilfield chemical automation for nearly a decade. We improve inventory accuracy and optimize routes with state-of-the-art tank level monitoring designed specifically for oilfield chemicals. By utilizing remote monitoring and wireless communications, your chemical pump will be fully optimized and working at a more efficient level in no time!

For just about ten years, AOF has been focused on perfecting oilfield chemical automation. Having a properly optimized chemical pump will greatly reduce your well and pump downtime, and get the job done with improved production capacities. Chemicals play a vital role in the oil and gas industry, and without the proper optimization, you could miss out on some major profits- not to mention the damage it could do to your equipment or the results of the production.

Oil field techniques and technologies are constantly evolving and changing, and that makes it even more important to have fully optimized equipment! Keeping your machinery up to date and running as smoothly as possible will minimize the possibilities of their systems failing or malfunctioning- something we understand you don’t have time for!

Call us today for a free estimate!

Optimizing your chemical pump can make a huge difference when it comes to the amount your company spends out in the field. Production and exploration companies tend to list production chemicals as one of the top expenses that they come across in the industry, so any opportunity to cut that cost down is a welcome one! Our background in the oil and gas industry gives us a unique understanding of the part that quality optimization plays in your production experience.

Want to Learn More?

Having a quality chemical pump is incredibly important in the oil and gas industry, as the chemicals can also improve the quality of production. The industrial chemicals can be used to improve your company’s quality assurance programs and sustain efficient manufacturing operations. As a result, they help maintain top-line revenue, cut waste, and reduce regulatory risk. With the right care taken to inject the right chemicals during your job, the life of the industrial machinery and equipment can be prolonged and the the entire process will be much more efficient: Many kinds of problems you might encounter through the operation- problems like stress and strain on the machinery, corrosion, erosion, and general external damage and wearing down- can be avoided with proper pump optimization.

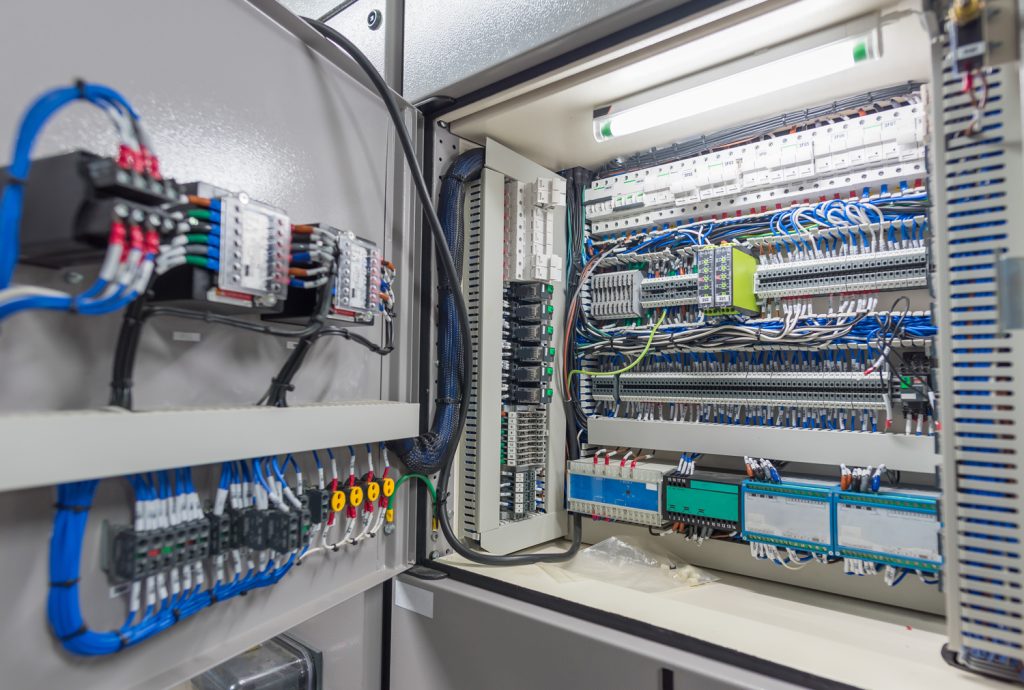

Many industrial organizations lack the necessary competencies to properly inject chemicals across their manufacturing assets in order to maintain product quality. Without a solid chemical management program, injecting the proper concentration of chemicals into the right areas at the right time might be difficult. Operators must have total visibility into their chemical injection pumps and systems- including real-time, automated data feeds that illuminate chemical injection performance- in order to be successful.

Want to Learn More?

Oil and Gas Industrial Automation Solutions in West and East Texas

Luckily, we have an entire team of highly skilled technicians who will be able to optimize your pump quickly and efficiently. You’ll be able to feel confident in your chemical pump’s efficiency after a visit from our team!